-

Eine Nachricht hinterlassen : info@aabindustrygroup.com

-

Telefon : +86 13951823978

Eine Nachricht hinterlassen : info@aabindustrygroup.com

Telefon : +86 13951823978

Beschichtungsadditive sind ein wichtiger Bestandteil von Beschichtungsformulierungen. Obwohl ihre Dosierung üblicherweise gering ist (0,1 % bis 5 %), haben sie einen erheblichen Einfluss auf die Lagerstabilität, die Anwendungseigenschaften, die Filmbildungswirkung und die endgültigen Filmeigenschaften von Beschichtungen. Das Auswahlprinzip von Additiven für Beschichtungen: hohe Effizienz, minimale negative Auswirkungen, hohe Wirtschaftlichkeit und Einhaltung von Umweltanforderungen. Im Folgenden werden die Auswahlmethode und die wichtigsten Überlegungen für Beschichtungsadditive beschrieben.

1. Hauptkategorien und Funktionen von Beschichtungsadditiven

Einstufung | Funktion | Beispiel |

Dispergiermittel | Verbessern Sie die Pigmentdispergierbarkeit, verhindern Sie Sedimentation und Flockung | Polyacrylat aund Phosphatester |

Netzmittel | Reduzieren Sie die Oberflächenspannung und verbessern Sie die Benetzbarkeit des Substrats | Organisches Silizium aund Alkindiol |

Entschäumer | Eindämmung der Schaumbildung und Reduzierung von Beschichtungsfehlern | Mineralöle; Organisches Silizium |

Verlaufsmittel | Verbessern Sie den Beschichtungsverlauf und reduzieren Sie Orangenhaut und Pinselspuren | Acrylester aund Organosilicium |

Verdickungsmittel | Passen Sie die Viskosität der Beschichtung an, um ein Absacken und Absetzen zu verhindern | Celluloseether, Polyurethan, Bentonit |

Antiabsetzmittel | Verhindern Sie Pigmentablagerungen und verbessern Sie die Lagerstabilität | Gasphasensilika, Polyamidwachs |

Aushärtungsbeschleuniger | Beschleunigen Sie die Aushärtung der Beschichtung und verbessern Sie die Reaktionseffizienz | Organisches Zinn, Amin |

Aushärtungsbeschleuniger | Verhindern Sie UV-Abbau und verbessern Sie die Wetterbeständigkeit | UV Absorber, Hals |

Fungizid | Hemmt Schimmelbildung und verlängert die Lebensdauer der Beschichtung | Isothiazolinone, Benzimidazole |

Haftvermittler | Verbessern Sie die Haftung zwischen der Beschichtung und dem Substrat | Silan-Haftvermittler, Epoxidphosphatester |

2. Schlüsselfaktoren bei der Additivauswahl

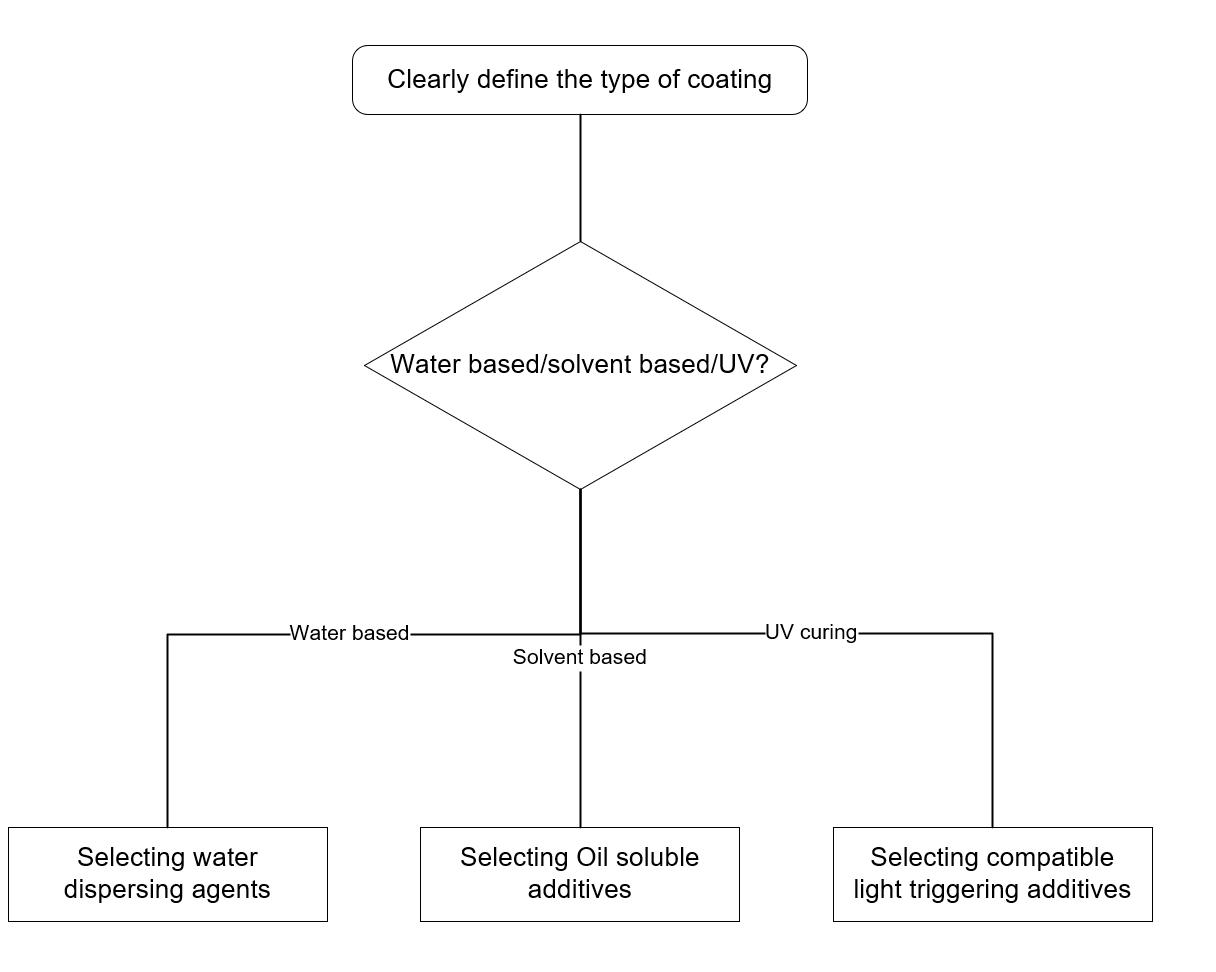

(1) Beschichtungssystem (wasserbasiert/lösemittelbasiert/UV-härtend)

l Wasserbasierte Lacke: Es müssen wasserlösliche oder wasserdispergierbare Additive (wie z. B. BYK-190 Dispergiermittel, Tego Wet 270 Netzmittel) ausgewählt werden.

l Lösemittelhaltige Lacke: Es müssen öllösliche Additive (wie z. B. BYK-161 Verlaufsmittel, BYK-011 Entschäumer) ausgewählt werden.

l UV-härtende Lacke: Es müssen photoinitiatorkompatible Additive (wie z. B. Verlaufsmittel Tego Rad 2100) ausgewählt werden.

(2) Beschichtungsart (Grundierung/Decklack/Klarlack/Farblack)

l Grundierung: Konzentrieren Sie sich auf Haftvermittler und Rostschutzmittel (wie Zinkphosphat).

l Decklack: Zu den wichtigsten Überlegungen gehören Verlaufsmittel, Mattierungsmittel (wie etwa Silica-Mattierungspulver) und wetterbeständige Zusatzstoffe.

l Farblack: Dispersions- und Antiabsetzmittel auf Wasserbasis.

(3) Bauweise (Spritzbeschichtung/Streichbeschichtung/Rollbeschichtung)

l Spritzbeschichtung: Es werden schaumarme Additive und Verlaufsmittel benötigt.

l Streichen/Rollen: Es sind Mittel gegen Ablaufen und Spritzen erforderlich.

3.Umwelt- und Leistungsanforderungen

Nachfrage | Empfohlene Zusatzstoffe |

Witterungsbeständigkeit | UV-Absorber+Hals |

Hochglanz | Verlaufsmittel + Entschäumer |

Matt/Silber | Mattpuder + Antiabsetzmittel |

Antibakteriell

| Schimmelhemmer+Algenhemmer |

Hohe Haftung | Epoxidphosphatester + Silan-Haftvermittler |

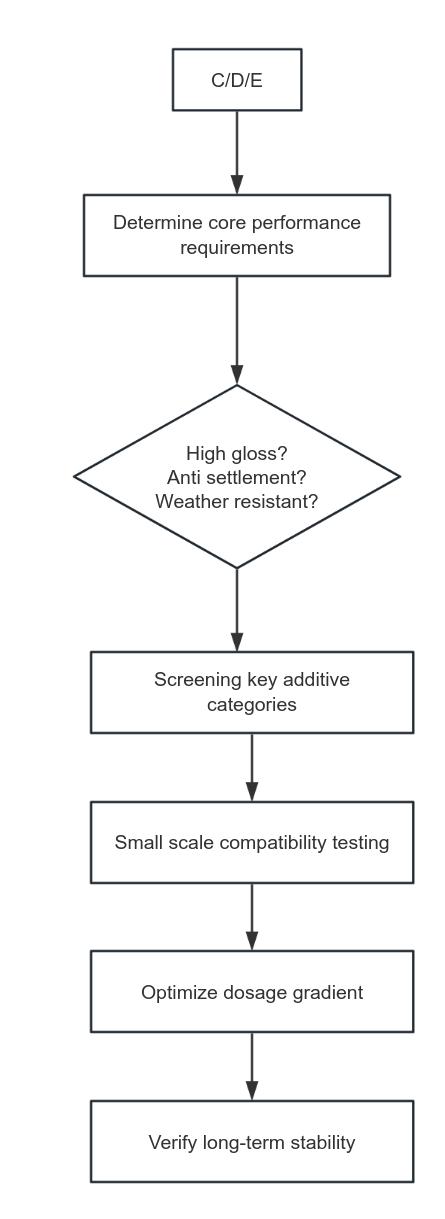

4.Überprüfen Sie die Langzeitstabilität

Führen Sie beschleunigte Alterungstests durch (z. B. 30 Tage lang bei 40 Grad lagern), um festzustellen, ob:

l Setzung (Antiabsetzmittel einstellen)

l Viskositätsänderung (Anpassung des Verdickers)

l Verminderte Entschäumerleistung (Hydrolyse der Entschäumer)

5.Häufige Probleme und Lösungen

Möglichkeitsanalyse | Lösungsideen | |

Schrumpfung des Beschichtungsfilms | Inkompatible Verlaufs- oder Entschäumungsmittel | Durch kompatible Additive ersetzen |

Pigmentsedimentation | Unzureichendes Dispergiermittel/Antiabsetzmittel | Antiabsetzmittel hinzufügen |

Schlechte Leveling-Leistung | Falsche Auswahl des Egalisierungsmittels | Umstellung auf organisches Silizium-Nivellierungsmittel |

Zu viel Schaum | Netzmittel haben starke Schaumeigenschaften | Entschäumer einstellen |

Schlechte Haftung | Unzureichende Benetzung des Untergrundes | Haftvermittler hinzufügen |

6.Allgemeine Auswahlideen

Das Material bestimmt die Leistung, und die sinnvolle Auswahl von Additiven kann die Anwendungsmängel von Beschichtungen deutlich verbessern. Es wird empfohlen, die Formel durch Experimente im kleinen Maßstab zu optimieren und den synergistischen Effekt zwischen den Additiven zu berücksichtigen. Nur durch die richtige Anwendung können sie ihr volles Potenzial entfalten.

China AAB Industrie-Technologiegruppe bietet ein umfassendes Portfolio an Additiven und Polymeren sowie einen detaillierten, individuellen Kundenservice zur Erfüllung spezifischer Anforderungen. Unsere wichtigsten funktionellen Additivprodukte umfassen: Netz- und Dispergiermittel, Entschäumer und Entlüftungsmittel, Netz- und Verlaufsmittel, Klebrigmacher und Haftvermittler, Wachsadditive, rheologische Additive, Hochleistungs-HAA-Härter, TIGC-Härter, GMA-Harze, Mattierungsmittel, funktionelle Verlaufsmittel, Texturmittel, Ladungsadditive, Dispergiermittel, Verlaufsmittel und Epoxidhärter, Pigmentdispergiermittel, Fließ- und Benetzungsmodifikatoren, Vergilbungsschutzmittel, Haftadditive usw. Unsere Kabasph®-Additivprodukte finden breite Anwendung in Autolacken, Reparaturlacken, Schiffslacken, Korrosionsschutzbeschichtungen, Holzbeschichtungen, Tinten, Epoxid-Bodenfarben, Pulverbeschichtungen, UV-Gel-Nagellack, Textilien, Gummi, Bautenanstrichen, bei der Papierherstellung usw., Kunststoffen, Hautpflegeprodukten, Kosmetika usw.

Wenn Sie technischen Support oder kostenlose Muster benötigen, können Sie sich gerne an uns wenden:

Tel: +86 13951823978 (WhatsApp, Telegram)

E-Mail: info@aabindustrygroup.com

Hi! Click one of our members below to chat on